Our country’s economy is moving along at an impressive pace. Consumer confidence is up while unemployment is at its lowest rate in decades. All of this is good news. An increase in employment rates means more money will be spent on goods and services. Those goods and services need promotional materials and packaging, which is good for all of us here at Westamerica. The problem is, greater demand for print materials means greater demand for paper. And demand can’t always keep up with supply.

Our country’s economy is moving along at an impressive pace. Consumer confidence is up while unemployment is at its lowest rate in decades. All of this is good news. An increase in employment rates means more money will be spent on goods and services. Those goods and services need promotional materials and packaging, which is good for all of us here at Westamerica. The problem is, greater demand for print materials means greater demand for paper. And demand can’t always keep up with supply.

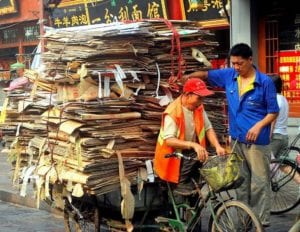

There are a number of outside influences that affect the demand for paper, which in turn result in increased costs. One big change that is having a major effect on the paper industry comes from China.

China and Paper Prices

As the world’s largest paper recycler, China uses both local and imported waste paper to produce pulp used in the production of recycled paper. Until recently, some 24% of this waste paper was imported from the United States, Europe, and other countries. At the beginning of 2018, China stopped accepting most waste paper, along with 23 other kinds of solid waste including plastic and electronic waste. Chinese officials have said the ban on importing solid waste is due to the environmental impact it has on the health of their people.

As the world’s largest paper recycler, China uses both local and imported waste paper to produce pulp used in the production of recycled paper. Until recently, some 24% of this waste paper was imported from the United States, Europe, and other countries. At the beginning of 2018, China stopped accepting most waste paper, along with 23 other kinds of solid waste including plastic and electronic waste. Chinese officials have said the ban on importing solid waste is due to the environmental impact it has on the health of their people.

This event has caused an enormous problem. China does a lot of printing and much of the paper they’ve used for printing came from the recycled paper they made from the imported waste paper. If China is no longer taking waste paper and turning it into pulp, they must now buy that pulp on the open market. Some estimates show that China is now consuming over 30% of the world’s pulp.

The second factor having a major impact on the cost of paper is the closing of a number of paper mills throughout the country. Georgia-Pacific, International Paper, and Kimberly-Clark are just three of the many paper companies that have closed some of their manufacturing facilities. This leads to a tightening supply of US inventory levels.

In 2017 there was a reduction in both coated and uncoated paper production and 2018 will see additional declines from 8-9% of these grades.

Transportation Costs

Another situation that’s having a negative impact on the paper industry is the rising cost of transportation. There are two significant factors causing the increase in transportation. First is the lack of truck drivers. The trucking industry needs to hire almost 900,000 more drivers to meet rising demand, according to an industry analyst.

Second is the cost associated with trucking has gone up. The Federal Motor Carrier Safety Administration enacted the electronic logging device rule or ELD mandate. Carriers must have installed ELDs to electronically record a driver’s “Record of Duty Status” by the end of 2017. This mandate, in part, has led carriers to increased contract rates by 10%-15%. Add to this, the increase in gas prices and you can understand the increase in transportation costs.

Westamerica Can Help

While these increased costs will affect all print vendors, at Westamerica we feel we are in a unique position to help mitigate some of these increases.

First, understand that paper and transportation are only part of the cost associated with your printed products.

Second, we have invested in equipment and employee training that can offset some of these increases.

For example, our Komori H-UV system reduces power consumption by 66% over a conventional UV press. There is also a significant reduction in makeready time and materials.

In addition, both our Komori and our digital presses have the ability to print on a wide variety of paper stocks. Our equipment allows for greater flexibility in paper choice, which allows you to select paper that meets both your design goals and your financial requirements.

Westamerica’s digital printing capabilities allow for more economical shorter runs, while our variable data printing capabilities allow us to run multiple versions of a job on the same stock at the same time.

In addition to our equipment, our highly trained team will help you design and produce your product in a cost effective manner. Our sales reps, CSRs, and designers understand the unique challenges you face in reaching your marketing goals. For example, something as simple as a slightly different paper stock, available in a different size, may meet your goals and result in a cost-effective product.

As these changes take place, I encourage you to reach out to our team for help. It’s important that we work together to help you realize your marketing goals.