Rumors about the new iPhone are all over the Internet. Some say there’s a new physical design that will include curved glass, inductive charging, and there may even be a change in the iPhone’s biometric recognition sensor.

Rumors about the new iPhone are all over the Internet. Some say there’s a new physical design that will include curved glass, inductive charging, and there may even be a change in the iPhone’s biometric recognition sensor.

Google has been testing self-driving cars. In just seven months, from October 2016 to May of 2017, their fleet of self-driven cars logged over three million miles.

And then there’s Elon Musk who wants to relieve freeway congestion by building 30 layers of tunnels beneath the 105 freeway in Los Angeles. He’s already started digging in the SpaceX parking lot in Hawthorne, California.

Embracing New Technology and New Opportunities

In the past couple of years, there have been a number of new technologies that have helped designers and marketers reach and engage current and prospective clients. These may not be as flashy as the new technology offered from Apple, Google and Elon Musk, but we’ve incorporated these new technologies into the products and services we offer. Our latest addition will provide numerous opportunities and advantages to our design and marketing clients.

The New Komori GL640 H-UV Printing Press

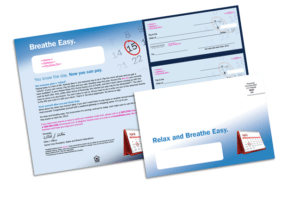

Westamerica Communications has just installed a new Komori GL640 H-UV printing press. There are a number of benefits that designers and marketers will appreciate about our new press. These include:

• Shorter Total Turnaround Time

• Improved print quality of traditional substrates

• Ability to print on unusual substrates

• Eco-friendly

One of the first advantages clients will realize with the new Komori press is the ability to get jobs finished quicker. There are a couple of reasons for the decreased turn around time. One is obvious. The speed of the press is amazing. Its maximum printing speed is 16,500 sheets per hour.

The second reason for the quick turn around time has to do with the ultra-violet (UV) lights used with the UV inks and curing system. Turnaround time is dramatically shorter than with conventional printing because an inline process cures printed items instantly. As soon as one side of the sheet is printed we can immediately flip the stock over and run the back side without having to wait for the ink to dry. And, once the substrate is printed, it can be delivered to the finishing department for trimming, folding, die cutting, or whatever finishing operations need to be completed.

Improved print quality of traditional substrates

The second improvement that designers and marketers will like is the improved print quality with traditional substrates. Let’s say you want to print a job on uncoated stock. Up until now, your biggest problem was, what we in the industry call, dot gain.

Uncoated paper is porous which means that solvent based inks soak into the paper. The dot of ink that is printed on an uncoated sheet will be absorbed into the paper thus the dot of ink will expand creating a muddy look to the text and images.

With the H-UV inks and curing system on the Komori, the dot of ink is cured so quickly that the inks don’t soak into the paper but instead set on top of the sheet thus creating an image with more contrast, brighter colors, and a bigger color gamut.

And, when printing with coated stock, there are additional benefits to the new Komori press. When printing coated stock traditional press operators use anti-set-off spray powder to make an air gap between printed sheets of paper. This powder keeps the ink on the front of one sheet from transferring to the back of the next sheet.

With the Komori H-UV system the inks dry (cure) immediately, thus there is a reduction of paper spoilage and without the need for anti-set-off spray powder, the surface of printed items is smooth to the touch.

And wait until you see the high gloss finish on coated stock. It’s so beautiful there’s no need to use varnish.

Ability to print on unusual substrates

Have you ever wanted to impress your clients by using non-traditional substrates? Well, now you can. Imagine printing on plastics, wood veneer, or cardboard. The truth is, if we can run it through the press we can print on it.

The Eco-friendly features of our new press

The new press has environmental advantages over both conventional printing presses and other UV presses. First, conventional presses that use solvent based or soy-based inks emit volatile organic compounds (VOC).

According to an article in Printing Impressions magazine, “Since UV inks cure instantly when exposed to UV light, drying time is eliminated and no solvents are released or absorbed into the substrate, as is common with conventional inks. The UV process releases no VOCs making it much safer for operators and the environment.”

There are additional advantages to the Komori over other UV presses. The H-UV lamp head is an ozone free lamp that operates with higher efficiency and less heat. The amount of CO2 emissions from the Komori is one-fourth that of conventional UV curing systems.

And we’re talking about a big difference in power consumption. Without getting too deep into the specifications of the press, the power consumption of a conventional UV press versus the Komori H-UV system is reduced by 66%. This all leads to a smaller environmental footprint.

The news of a new Komori GL640 H-UV printing press installation at Westamerica Communications in Lake Forest, California may not make headlines like Elon Musk digging a hole in Hawthorne, California, but it’s a big move for us and our clients who will soon see the opportunities that are available from embracing this new technology.

I recently ran into an old business acquaintance at a social event. We shook hands and talked about old times. When we finished our conversation, I handed him my business card. In return, he offered his card, but before he handed it to me, he took out a pen, crossed out his old email address and wrote in a new one.

I recently ran into an old business acquaintance at a social event. We shook hands and talked about old times. When we finished our conversation, I handed him my business card. In return, he offered his card, but before he handed it to me, he took out a pen, crossed out his old email address and wrote in a new one.